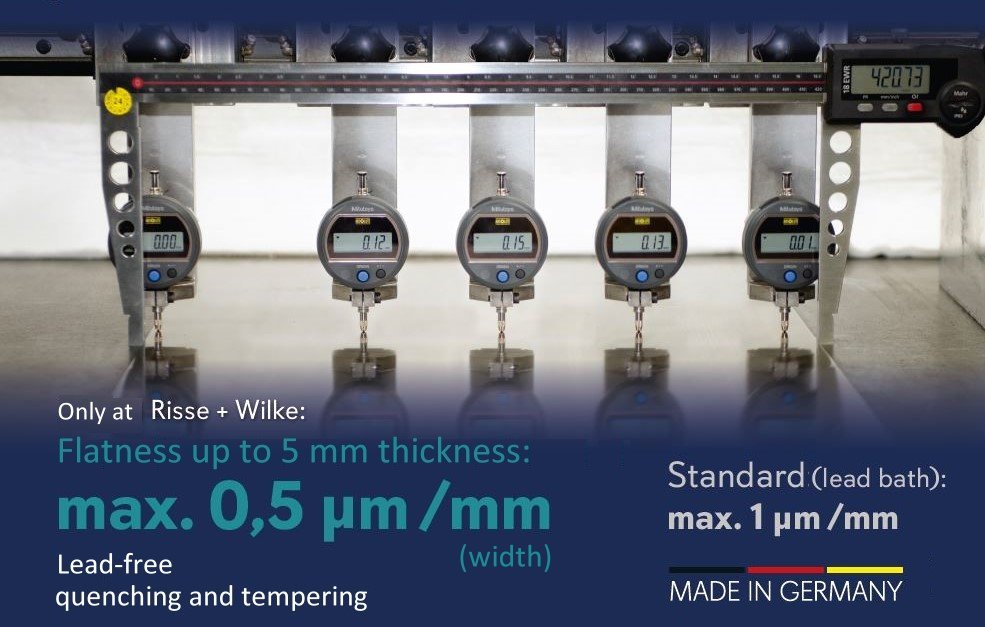

Excellent-flatness. Quenched and tempered. Lead-free.

LET'S TALK ABOUT FLATNESS.

Lead-free QT-steel combined with

Top-Flatness.

Hardened steel strip - Tempered lead-free with excellent flatness.

Unique selling point!

Our hardened steel strip, which has been tempered lead-free, offers an exceptional flatness. This unique combination of lead-free tempering brings numerous advantages in the manufacturing process and provides significant customer benefits.

Customer benefits

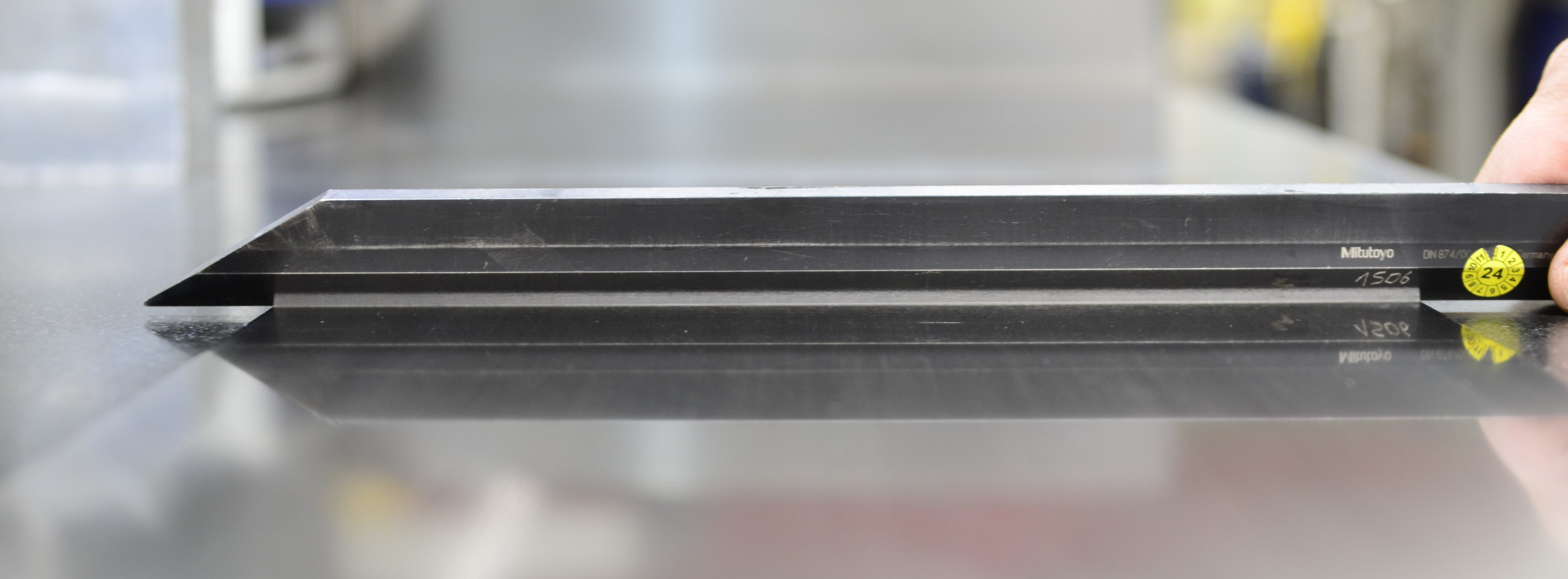

Higher precision:

The excellent flatness enables more precise processing and reduces deviations during further processing steps.

Improved quality:

The uniform flatness increases the quality of the final products, which leads to a higher customer satisfaction.

Less waste:

Due to the exceptional flatness, waste in production is minimized, reducing costs and increasing efficiency.

LET'S TALK ABOUT FLATNESS.

Advantages

Optimized processing:

The uniform flatness of the strip steel facilitates further processing steps and reduces tear and wear on machines and tools.

Reduced post-processing:

Due to the high flatness of the steel strip, the necessity for rework is reduced, ergo saving time and costs.

Technical features:

- Improved material properties

- Reduced material tension

- Reduced straightening operations

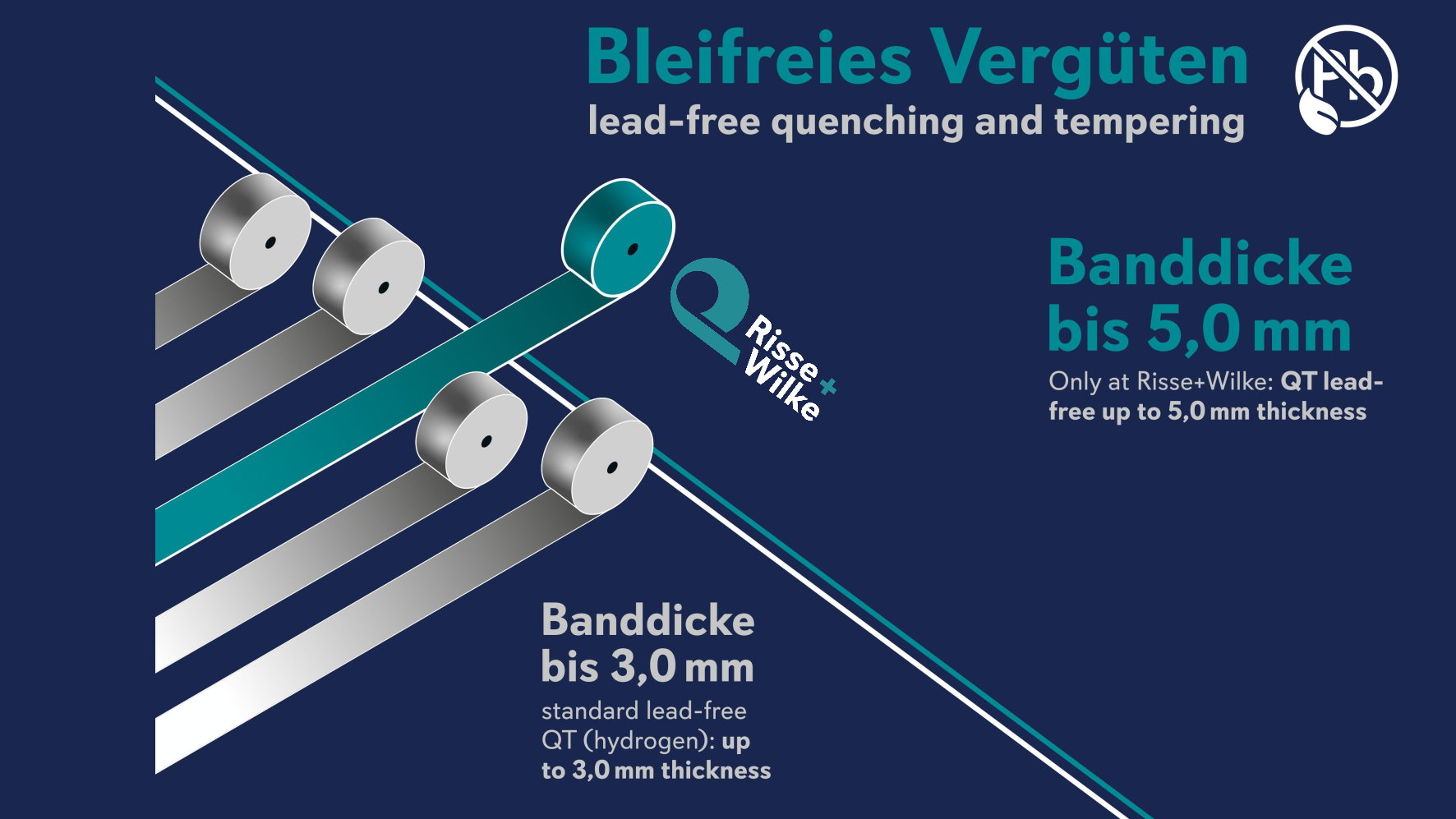

A new approach to proven technology!

New dimensions:

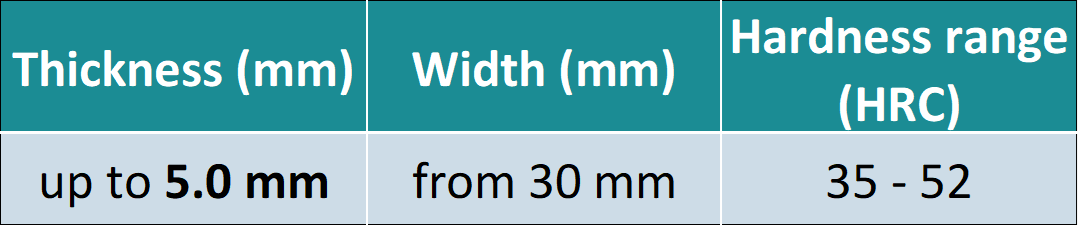

Extended range of dimensions and grades as well as > 3 mm thickness

Proven and extensively tested up to 5 mm

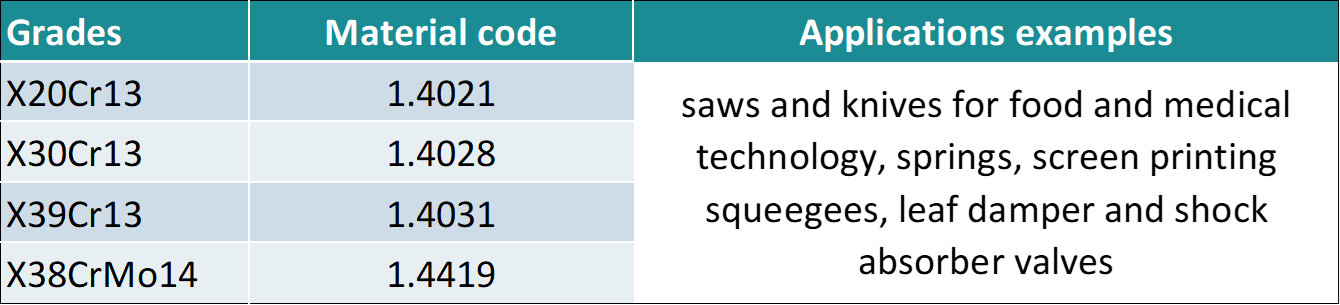

New applications (lead-free), e. g.:

in medical technology,

food industry and many others.

Continuous development

Get in touch with us!

Lead-free quenching and tempering up to bis 5 mm thickness

Unique selling point!

Let's talk about ...

... lead-free quenching and tempering of steel strip.